Foamatomatic International Technologies

The perfect FIT for your factories, delivering exceptional solutions and expertise to the foam and mattress industries.

Best Service in Industry

At Foamatomatic International Technologies, we are dedicated to providing the best service in the foam and mattress industries.

Recognised Name in Industry

This recognition is a result of the extensive experience and expertise of our directors who have a deep understanding of the intricacies of these industries.

Expert Team Support

Our directors and employees have vast experience in the foam and mattress industries, ensuring that we have a deep understanding of the unique challenges and requirements of our clients.

Categories

Looper Machine

First ever Indigenous Looper is designed for splitting of long blocks up to 60 meter in Roll form at a max cutting speed of 120 Meter/minute. The feeding bridge in the stationary tower is electrically controlled and is used for opening and closing the circular track. It allows the feeding of the block into the long splitting machine. Moveable by motor-driven rope winches

Automatic Mattress Packing Machine

The machine can handle mattresses with a maximum size of 82 x 84 Inch and a minimum size of 36X60 Inch. The machine can wrap up to 2 wraps per minute, indicating a relatively high wrapping efficiency. The machine is capable of adjusting itself to accommodate different sizes of mattresses. It likely has an automated length-width-height measuring system, allowing it to adapt to various mattress dimensions without manual adjustments.

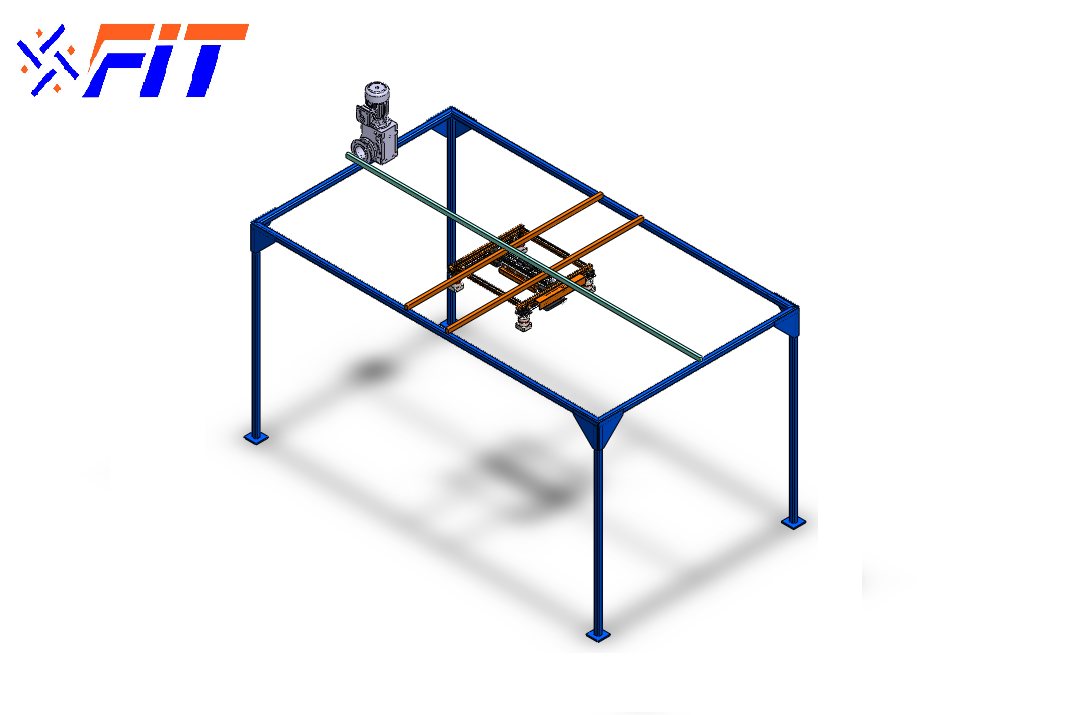

Small block automation system

Customized solution according to plant layout and requirement of automation.

Small block system consists of block stacker shuttle , pop-up and telescopic conveyors to feed blocks on circular machines, this will help to reduce the touch points and no need to roll out the blocks on floor from vertical cutting to circular machine, results improving yield.

About us

Welcome to our website! We are thrilled to share that our expertise in the foam industry goes beyond just understanding the market – we have successfully developed a range of machines from scratch to cater to various needs within the industry. One of our notable accomplishments is the development of the Looper technology, which has revolutionized foam manufacturing processes in India. The Looper machine, designed and created entirely in-house, has brought about significant advancements in productivity and efficiency, setting new standards in the industry.

Our Projects

IPF Long Blocks Handling System – Joyce foams

ADELAIDE, AUSTRALIA, 2023

We are proud to announce the successful installation of the IPF long block system for Joyce Foams in Adelaide in 2023. This project underscores our commitment to delivering advanced, sustainable solutions in the foam industry.

IPF Long Blocks Handling System – Foamline

KRASNOYARSK, RUSSIA, 2023

We are excited to announce the successful installation of advanced systems at Foamline’s facility in Krasnoyarsk, Russia. This project highlights our commitment to delivering innovative and efficient solutions in the foam industry.

Shree Malani Foam

BHUBANESWAR, INDIA, 2024

We are delighted to announce the successful completion of an upgrade project at Shree Malani Foams in Bhubaneswar, India, in 2024. This project highlights our commitment to enhancing operational efficiency and capacity in the foam industry.